This module has been well informative and allowed the group to successfully design a crane to fit a given brief, in accordance to BS standards.

It was important to choose the most suitable crane design from the large variety found in the first week: gantry, jib, tower crane, bridge crane, stacker crane... Ultimately after a long debate, the group chose a gantry type as it best suited the scenario and had the best chances of working productively in accordance to the brief.

Calculations, materials and costs were continuously assessed and reviewed by each member of the group to ensure faults were quickly located and the final design could be altered accordingly.

The main issues brought up during the presentation were:

• Beam length (5.5m) which was noticeably long, but the team had originally accounted for this situation and researched into alternative scenarios including splitting of the beam into several sections. This was found to be impractical, costly, time consuming and would increase stresses, shear and bending forces which the beam would experience (increasing safety issues).

• Shoulder head would be more costly than calculated due to its unique design

Overall the group worked effectively for most of the duration of the project and despite a couple of setbacks, quickly produced action plans in order to assess the situation, compensate and work efficiently to finish the crane and avoid missing the deadlines.

A troubling issue, which was ultimately resolved, was the lack of communication between two members and the rest of the group at various intervals of the project. This included the first 3 weeks where the materials specialist was absent as a result of illness but had not informed the team during this time in order to allow the rest to compensate and to send information regarding progress. The other occurred when it was not possible to contact the stress analyst during the time of the Easter Holiday in order to inform of the issues found with the initial set of calculations for the I beam.

Sunday, 2 May 2010

System Analyst Project Review

In general the project ran smoothly throughout the period, and due to a strict schedule the progress in which the project developed was smooth and of a quick pace. During the Easter holidays the work was carried on, despite a little communication issue, the level of work stayed constant.

Over the holiday period I was out of contact for the beginning of the holidays and it was only towards the end of the holidays that I was able to get in touch with any of the group. This slowed down the rather rapid pace that had been maintained for the beginning of the project slightly. However as soon as contact was re-established then I was able to get back up to speed with the rest of the group without any problem.

Our Materials Expert was absent for the first few weeks of the project, and after finally get a hold of him we found out it was due to illness. However apart from this little hiccup when the work was set he was able to perform at the level desired.

One of the major difficulties that arose for me was the continuous alterations of the beam, so therefore the amount of times the force analysis had to be done for each new design. The method would have been easier if a set model was created on a program like excel and the calculations could have been produced much quicker. However with the final design being of British Standards we were able to compare our calculations with benchmarks so we knew that the system would not fail and we weren't just taking a stab at it.

One of the main problems with the design was that the main component of the crane, the beam, was not collapsible so it could only be transported on either the top of the land rover type of 4x4 or on the landing booms of a helicopter, instead of in the loading bay with the actual kit. This is a restriction of the design but weighing that against critically weakening the design I believe it was the right path to take.

Overall the project went well and through the vigilance of the project manager, who made sure everything was to be done quickly and efficiently were able to complete the project without having to rush anything.

Final Chart

The following action plan was produced to take into consideration the new deadlines for the final project, the Easter holidays which caused communication issues between some team members and the time delay caused by the unexpected review of the stress analysis which obtained the final design (according to BS standards).

The tasks below show the project has been complete and to a great extent followed the new guidelines in order to avoid overrunning and missing deadlines.

The tasks below show the project has been complete and to a great extent followed the new guidelines in order to avoid overrunning and missing deadlines.

Friday, 30 April 2010

Cheif Designers Project Review

I believe this project went well and that we worked well as a team. We remained on schedule for the first stage and , due to continuous work from the group over the Easter holidays, were able to complete the project on time despite some set backs.

The greatest problem we faced was that two of our group members were missing for approximately three weeks each at different stages of the project. Our materials specialist was absent due to illness at the start of the project, and our stress analyst was not contactable over the Easter holidays due to a breakdown in communication. The remaining group members however worked well around these losses and those who did miss part of the project worked hard upon their return to make up for their loss, in order to produce the final crane to a high standard.

The second set back occurred towards the start of the Easter break when it was realised that the main beam needed redesigning. This set us back about a week, though did give us the opportunity to redesign the beam to British standard dimensions.

The greatest flaw in the design that was picked up in the Q&A section of the presentation was that the beam, at 5.5 metres in length, was on the border of being impractically large. This was a problem that we had considered, though splitting the beam would have weakened it significantly. If I had more time for this project , I would spend much of it considering possible solutions to splitting the beam. In addition, the design of the head piece of the shoulder component would be difficult to manufacture for a reasonable cost.

In conclusion, though we had a few issues, I believe this project was a success, and that we completed it to a high standard as well as to specification.

The greatest problem we faced was that two of our group members were missing for approximately three weeks each at different stages of the project. Our materials specialist was absent due to illness at the start of the project, and our stress analyst was not contactable over the Easter holidays due to a breakdown in communication. The remaining group members however worked well around these losses and those who did miss part of the project worked hard upon their return to make up for their loss, in order to produce the final crane to a high standard.

The second set back occurred towards the start of the Easter break when it was realised that the main beam needed redesigning. This set us back about a week, though did give us the opportunity to redesign the beam to British standard dimensions.

The greatest flaw in the design that was picked up in the Q&A section of the presentation was that the beam, at 5.5 metres in length, was on the border of being impractically large. This was a problem that we had considered, though splitting the beam would have weakened it significantly. If I had more time for this project , I would spend much of it considering possible solutions to splitting the beam. In addition, the design of the head piece of the shoulder component would be difficult to manufacture for a reasonable cost.

In conclusion, though we had a few issues, I believe this project was a success, and that we completed it to a high standard as well as to specification.

Thursday, 29 April 2010

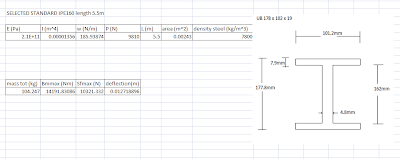

Final dimension sizes for I beam

Exploded crane animation

This is the animation describing the assembly of the crane.

The colour scheme is arbitrary in this video, designed to allow the viewer to differentiate easily between components.

Safety - Tools

It is highly advisable to tighten the U-bolts by hand with a spanner rather than with a torsion torsion wench. It is also advisable to use a spirit level to ensure that the beam is horizontal before loading the crane to minimise the chances of the hoist slipping along the beam.

Subscribe to:

Comments (Atom)